Download

PEDAS-Foundation

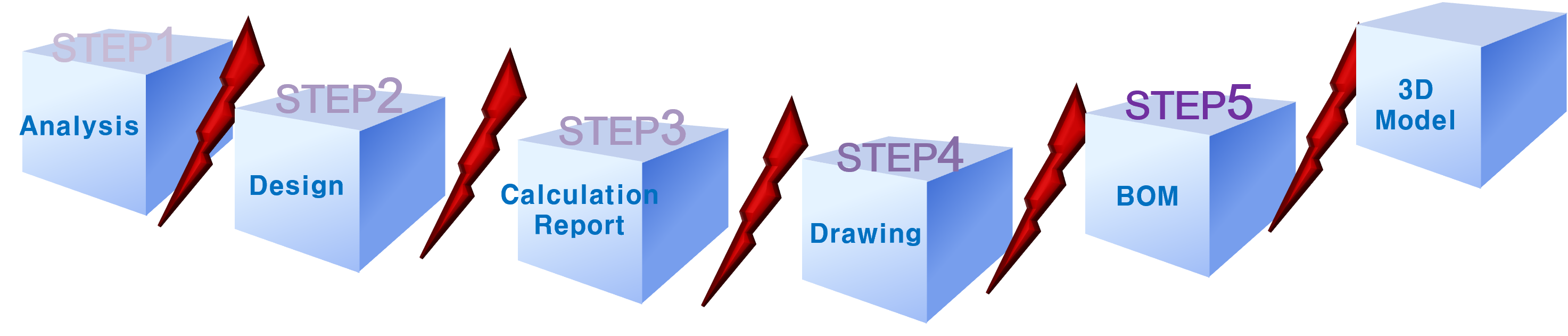

Analysis & Design

3D Modeling Basis

Calculate Report & Drawing

Calculation

The most Drawing

BOM

3D Modeling

Saving = Time*Money

Economic Product

Optimized BOM

Optimized Demand Strength

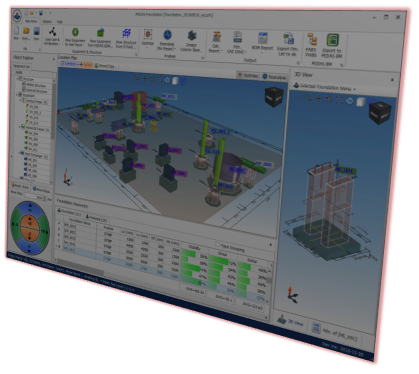

Interchanging 3D Modeling

Integrating Separate Structural Works

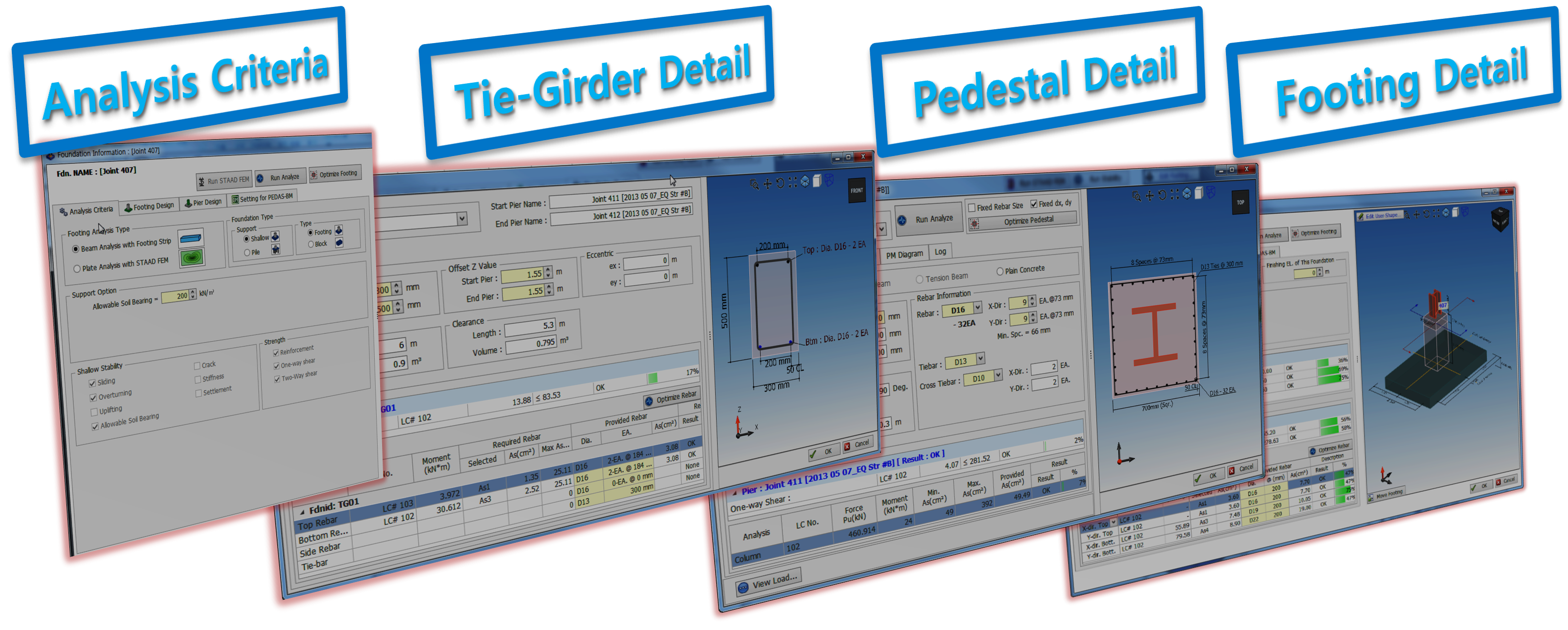

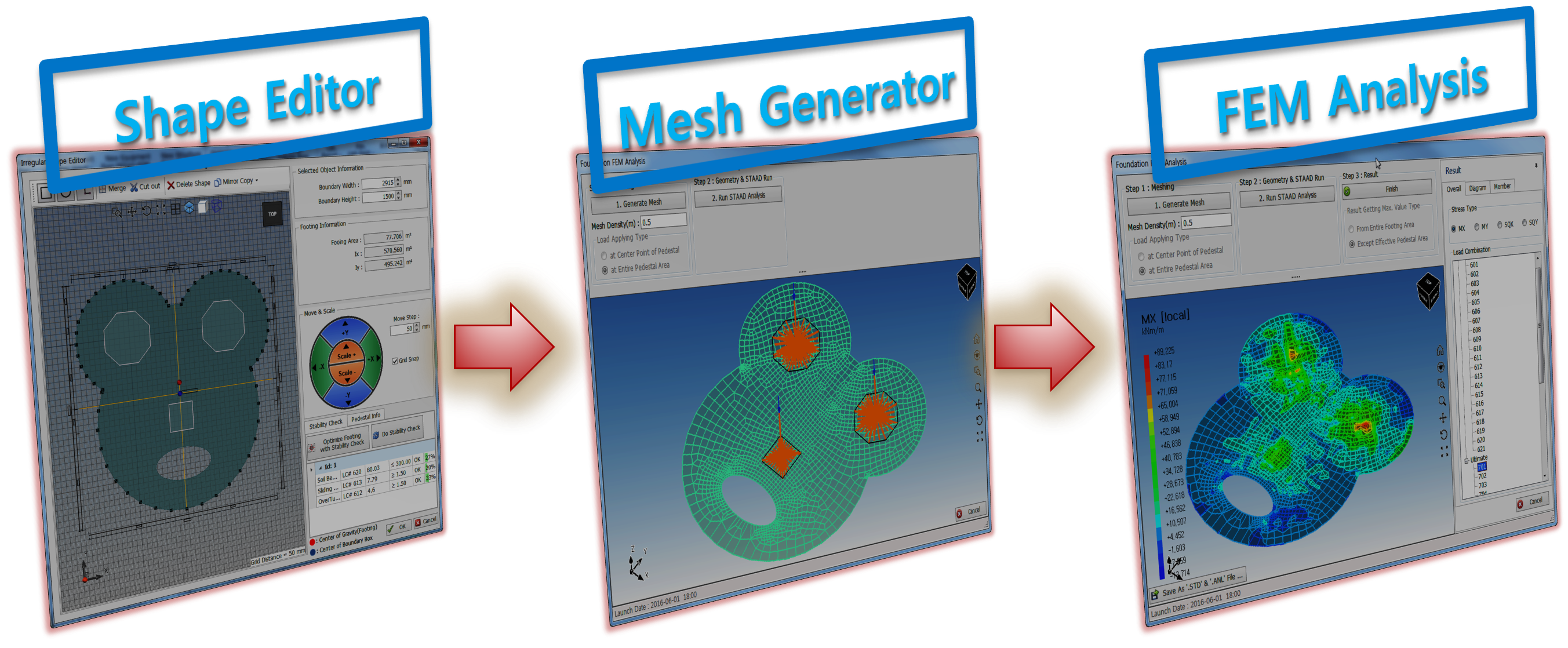

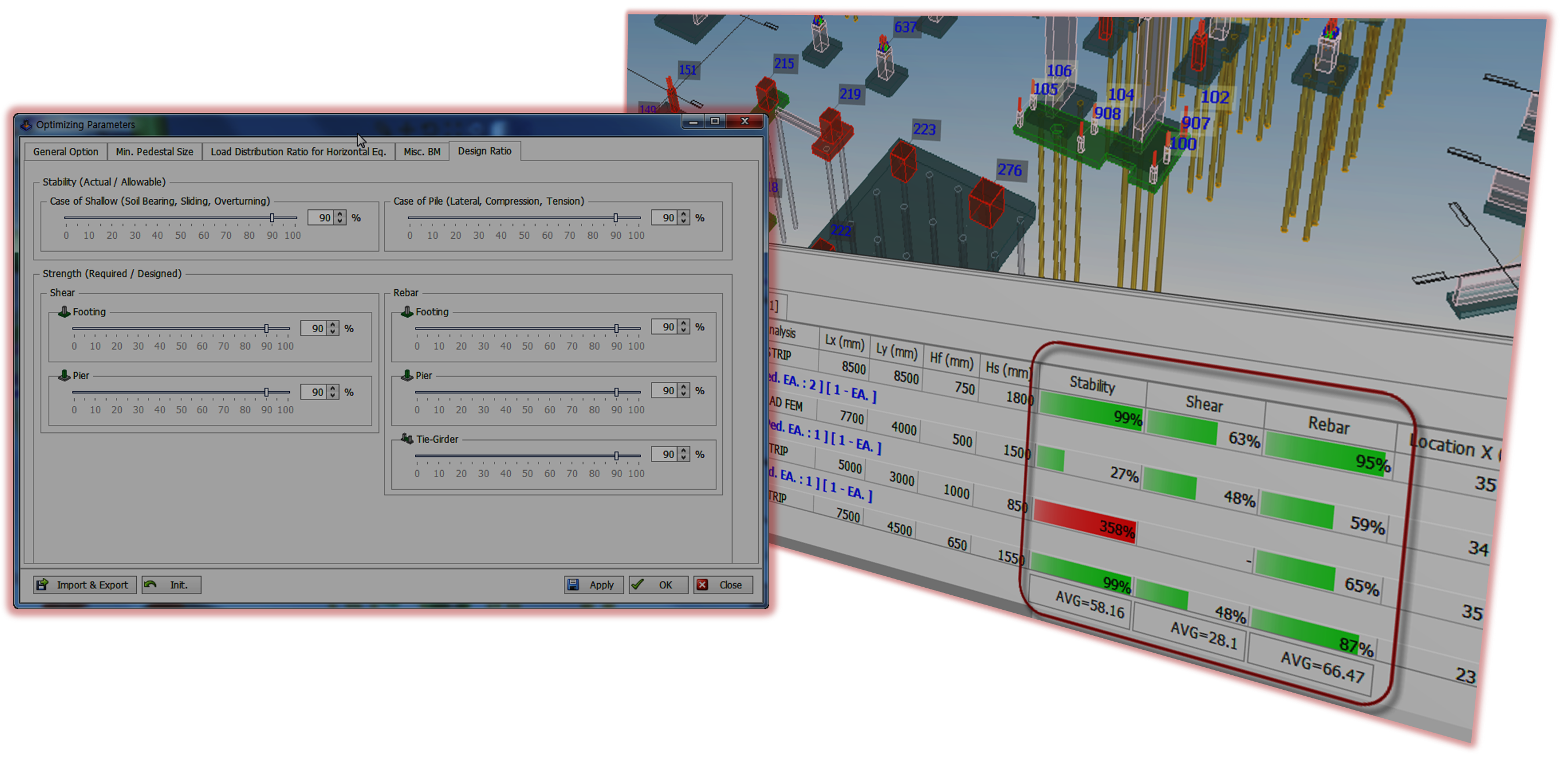

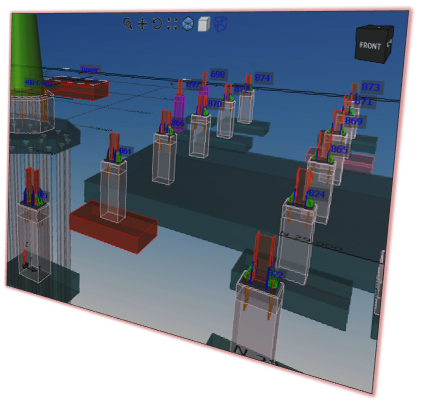

The process involves performing optimized designs for stability, shear, and rebar, setting design ratios based on the type of footing, pedestal, or tie-girder, and providing an easy review for the design reviewer with a progress bar for visualizing design results.

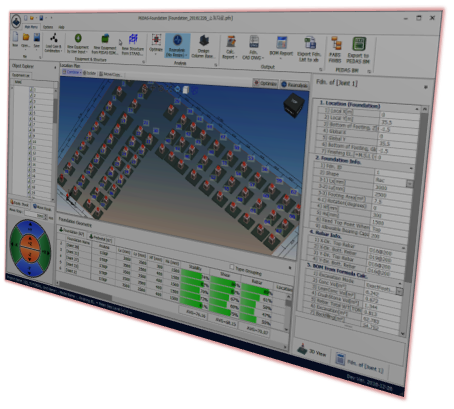

The features include selecting load combinations, setting location and rotation for structures, setting grid names, importing multiple STAAD models simultaneously, and auto-grouping by foundation type after design.

The features include batch processing design for equipment foundations by area/unit, notifying alterations of equipment data during revisions, and designing individual equipment data based on user inputs if PEDAS-EDM is not utilized.

The process involves analyzing and connecting the column base design of structure piers with PEDAS-Column Base, and sharing the geometry information and analysis results.

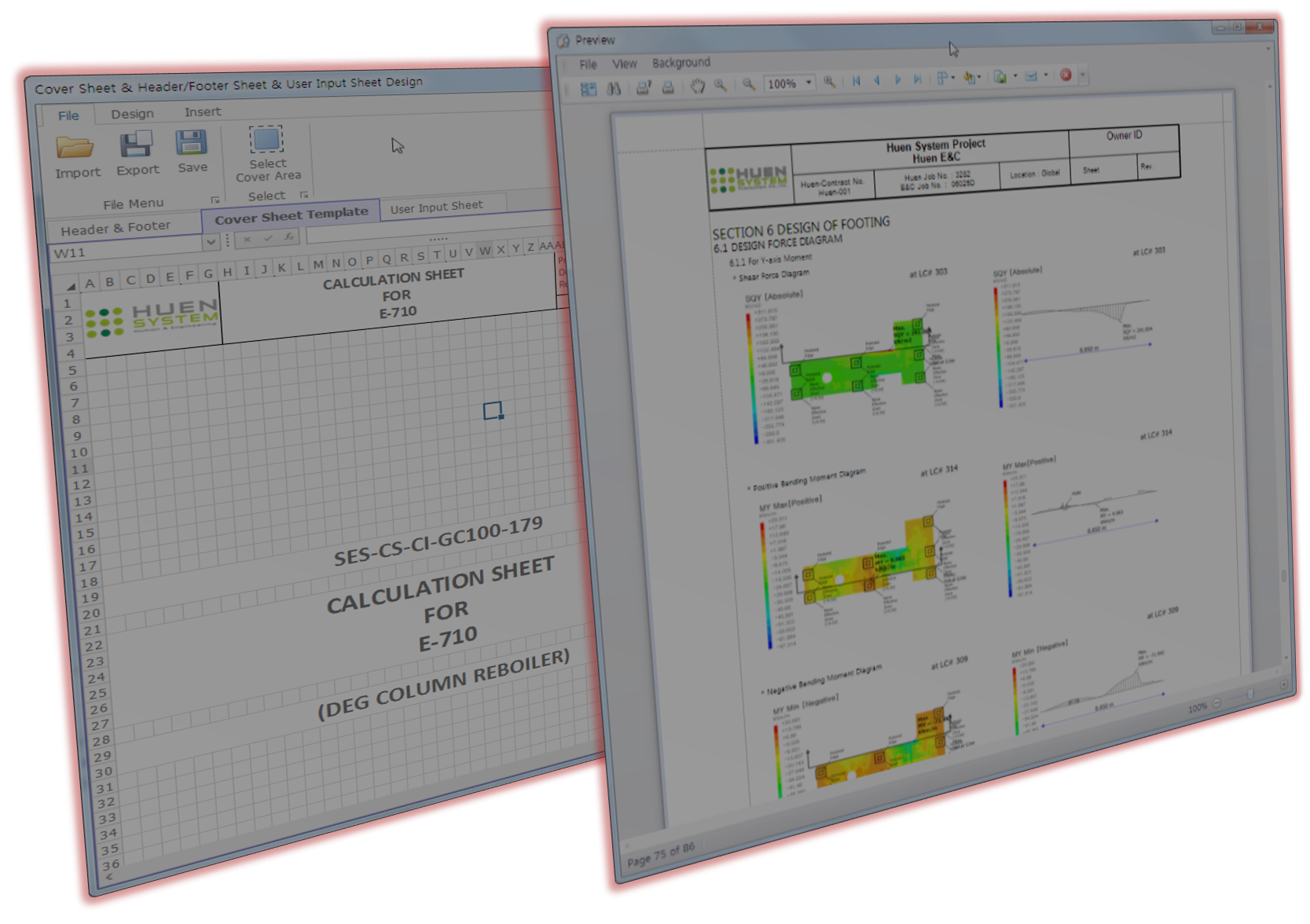

The functions include editing titles and contents, adding customized contents with Excel compatibility, editing and setting cover sheets, headers, and footers with Excel compatibility, and producing reports in PDF and Excel formats.

The system features include producing detailed BOM reports, automatically calculating bar-bending schedules, and producing detailed drawings for foundations and pile locations.

| Korea | |

|---|---|

Korea Korea |

Hyundai Engineering  GSE&C

SK ecoengineering

GSE&C

SK ecoengineering  Hyundai E&C

Hyundai E&C  Samsung C&T

Samsung C&T  Toyo Engineering

Toyo Engineering  S&I Corporation

S&I Corporation  Byucksan Engineering

Byucksan Engineering  Alpex E&C

Pields Engineering

Hi-Tech Engineering

Alpex E&C

Pields Engineering

Hi-Tech Engineering

|

| Global | |

|---|---|

India India |

GS E&C Delhi

|

Indonesia Indonesia |

Rekind |

Poland Poland |

BIPRORAF Sp. z o.o. |

France France |

Technip Energies

|